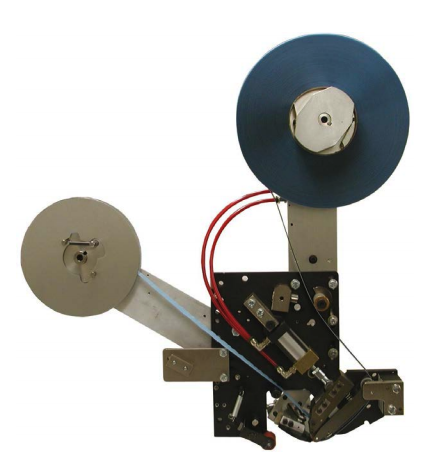

The SD-658-1-Tape Applicator is designed to apply various lengths of pressure sensitive VHB, foam or butyl tapes with liner removed or liner in place. A rotary knife provides a smooth cut on the ends of the tape. The SD-658-Tape Applicator applies tape to a moving product or can be traversed across the product which pulls the tape from the applicator.

Options For The SD-658-1 Tape Applicator System

- Complete material handling systems.

- Liner rewind for applying tape liner removed.

- Product heater system to improve tape bonding

- Control systems to start and stop the tape application.

- Tape low sensors.

- Tape fail sensors.

- Level unwinds with nip roll for liner takeaway.

- Tape applied sensors

Product Specifications For The SD-658-1

- Tape Roll Size: 18” (457mm) OD – 3” or 3 ⅞” (76 mm or 98 mm) ID Core

- Tape Accuracy: ±1/16”

- Tape Width: ¼” – 1” (25 mm)

- 14” minimum center to center distance between two strips of tape, liner removed

Tape Applicator Machine & Power Specifications

- Electrical: 24V DC or 115 V AC, 50/60Hz

- Air: 80 PSI (550 kPa)

- Size: 15” long (24” long with liner rewind) x 8” wide x 21 ½” high 27 wide x 26 deep x 19” high

- Speed: Variable up to 40’ per minute depending on the product

- Weight: 30 lbs. approximately with liner rewind

Technical Data Sheet

View the Technical Data Sheet for more information.

Discover What Straub Design Can Build With You

Ready to build your SD-658-1 tape applicator? Give us a challenge. We’ll deliver the tape application system or web converting system that’s exactly what your business requires. Our engineers have created many custom solutions, from simple machines to complex systems. Contact or give us a call at 952-546-6686 to get started.