Custom Tape Application Systems

Solutions That Improve and Automate Production

Do you have a unique tape application challenge? While Straub Design offers many off-the-shelf products and systems for various applications, there are times when you need a custom solution tailored to your needs.

Our engineers are among the most talented and creative in the business and have provided solutions to some of the most complex applications. They work closely with you, step-by-step, to understand your challenges and design the right solution. Capabilities include tape application automation, web and material handling, converting, and other specialized applications.

How Our Custom Design Process Works

Whether you are local or located internationally, our team is here to help. We are willing to travel anywhere to partner with you to design a custom tape application system that works for you! Here is what you can expect when working with Straub Design:

Consultation

It all starts with a conversation. You might have a manual process you want to automate or are looking for ways to improve how a piece of production equipment operates. We take time to understand your production setup, product type, and productivity goals to determine potential solutions, whether that is a modified system from stock or a custom-built system.

Production equipment is a significant investment, and we promise to always be transparent about costs upfront. We also discuss your budget throughout the project so there are never any surprises.

Design

After discussing your tolerance requirements and production needs, our engineers use sophisticated CAD software to design your system and create a model for proof of concept. You will have a clear idea of how the machine operates and integrates with your existing equipment to ensure you receive a solution that sticks.

Build & Test

Upon design approval, we build your custom tape application system and conduct thorough testing to ensure all components operate correctly. This process includes testing the machine with the same materials you plan to use in your production line. You receive regular timeline updates during the build and testing from our team.

Deliver & Consult

When it’s time for delivery, our staff can provide on-site consulting by request and help your team set up and test the machine to ensure it works exactly as required. With all design, testing and fabrication of the system performed in-house at Staub Design, you can count on consistency and quality in building your custom tape applicator or web handling system.

Talk to a Straub Design Representative

Unique challenges require creative solutions. With experience helping customers across various industries, our engineers know how to find the right solution for your business. We build custom tape application systems and converting systems for all applications, whether you need to adhere tape to a road surface or a retail end-cap display.

You can always count on receiving a response from our team within one business day of your contact request!

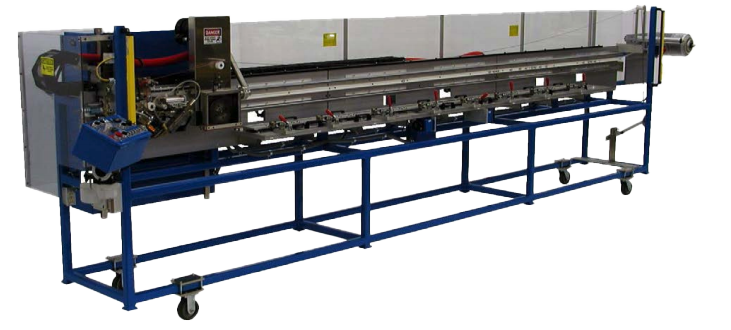

Integrated Custom Tape Applicator Systems

When you need equipment—automatic assembly, custom web handling systems, labeling systems, and automated taping machines—we can build the solution you need. Straub Design’s engineers have extensive experience developing and manufacturing equipment that fits seamlessly into your workflow.

Look to us for integrated solutions ranging from ultrasonic welding to inspection, laser tape cutting, spring winding, and automated parts handling. You can also specify vision inspection in single or multiple applications, as well as incorporate a variety of elements, including:

- Electronic and mechanical assembly

- Inspection

- Measurement tasks

- Parts counting, sorting, and more

Developing Solutions for High-Volume Packaging Operations

Speed is key in high-volume packaging. The machines and systems used in large-scale conditions must be built to handle different environments and be fail-safe at crucial times.

The packaging industry is one of the biggest industries we work with for custom projects. Our tape applicators are among the best in the industry, and we can create machines that can be mounted over a moving part or added to a conveyor. We design and build systems that are easy to implement and help you maximize line uptime. Careful engineering and testing ensure your custom solution withstands the demands of your operation.

Automating Tape Application Processes for the Automotive Industry

Highly automated operations require solutions that combine innovation and practicality. When it comes to tape application systems for the automotive industry, Straub Design is your go-to. The machines we design help you maximize return on investment and provide a custom solution for your unique challenges and processes. From processes applying heat bond, flock tape, or pressure-sensitive tapes, we understand the auto industry and can design a solution that sticks.

Helping the Print Industry Operate with High Efficiency

Over the past few decades, the print industry has required products to be created and shipped faster than ever. In a world where speed and efficiency are crucial, Straub Design works with you to develop standalone tape application systems or tape applicators that can be integrated with your existing equipment.

Examples of machines we’ve designed for the print industry include custom tape applicator systems for overnight envelopes, book boxes, and specialty mailers. Systems can be designed to apply adhesive transfer tapes for sealing products and tear tapes.