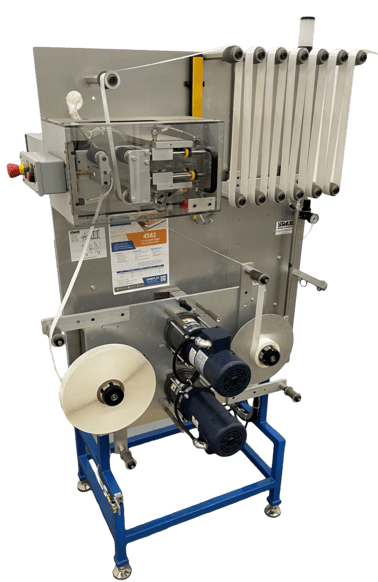

SD-660 Automatic Tape Splicing System

The SD-660 Automatic Tape Splicing System allows operators to splice a depleted tape roll without stopping the production line. By holding two tape rolls, the SD-660 automatically switches to the second roll when the current one is finished allowing for production to continue running as the operator replaces the used tape roll.

The tape splicing system provides enhanced safety measures by eliminating the need for operators to change tape rolls on a moving line. SD-660 increases efficiency and safety standards.

SD-660 Features

- Includes the frame for a standalone tape splicing system

- Ability to control two applicators: Tear applicator along with the standard applicator to eliminate the need for a separate controller

- Easy to set up and operate by mounting tape on the turret and rotating to replace the empty tape roll

SD-660 Product Specifications

- Tape: Pressure-sensitive tape (PSA), single or double-sided (adhesive transfer tape may not work with this tape splicing system)

- Tape Width: Min: 3/4” (19mm); Max: 2” (50.8mm)

- Tape Roll Size: Planetary wound rolls; up to 18” outer diameter (OD); 3” inner diameter (ID) core

- Speed: Up to 700 FPM (213 MPM)

SD-660 Machine Specifications

- Electrical: 120V, 1Ph, 60Hz, 15A

- Size: 42” wide x 48” deep x 78” high

- Weight: 425 lbs

Check out our Technical Data Sheet, or contact Straub Design to discuss system capabilities specific to your production needs.

Customize Your Automatic Tape Applicator

We are engineers, inventors, and solution seekers. Give us a challenge, and we’ll deliver a pressure-sensitive tape application system that meets your unique production requirements. With experience creating everything from simple machines to complex web converting systems, our engineers can develop the perfect solution for you! Contact us or call 952-546-6686 to get started.